|

EIA Reference

|

Recommended

Environmental Protection Measures/ Mitigation Measures

|

Objectives of the

recommended measures & main concerns to address

|

Implementation

Agent

|

Implementation

Stage

|

Implementation

Status

|

Relevant

Legislation & Guidelines

|

|

D

|

C

|

O

|

|

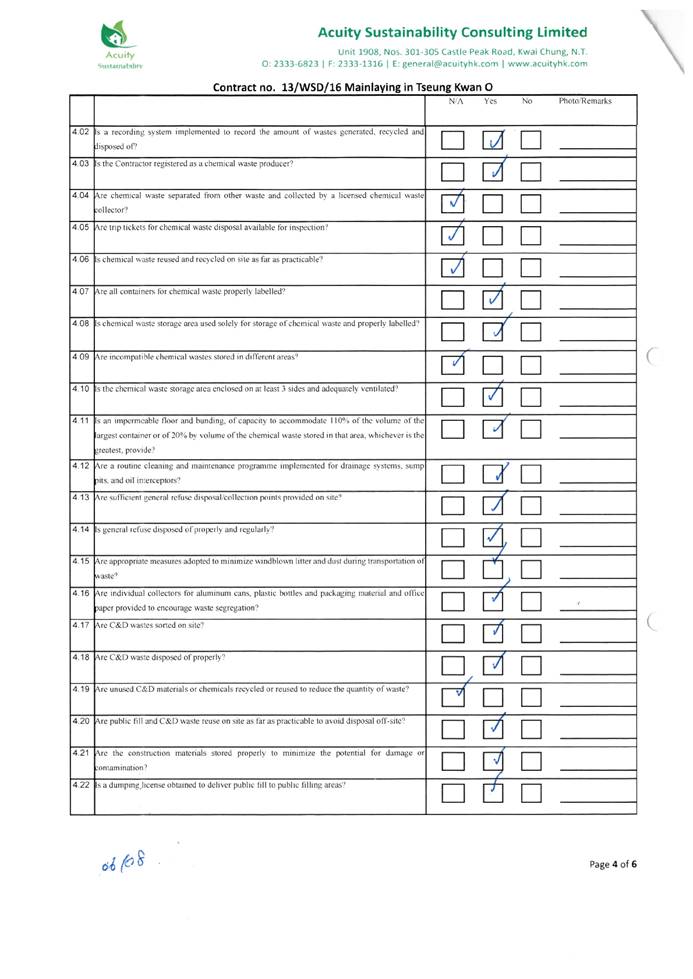

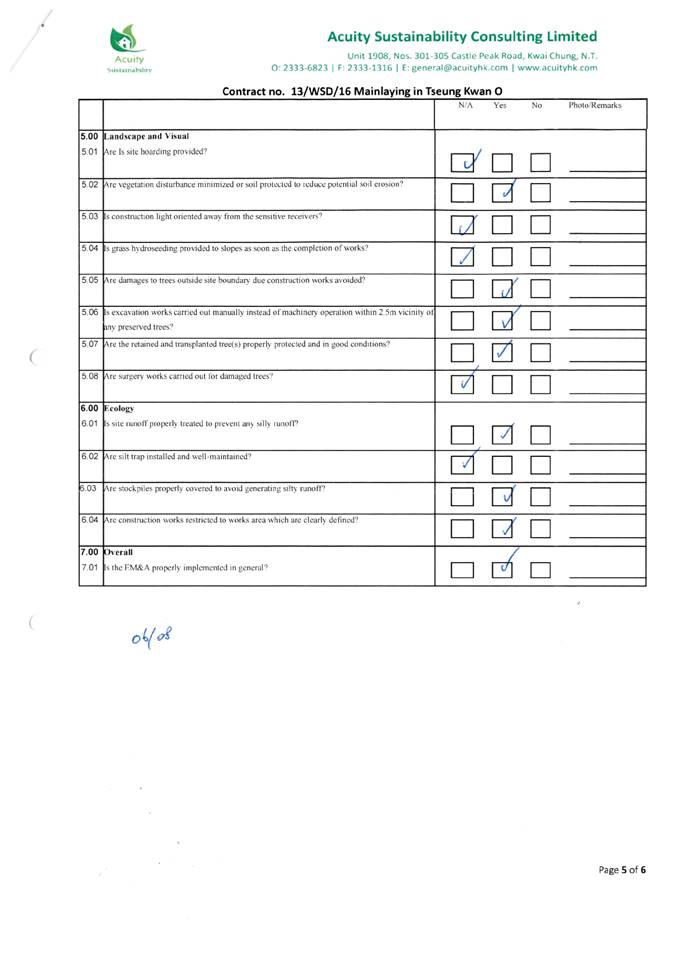

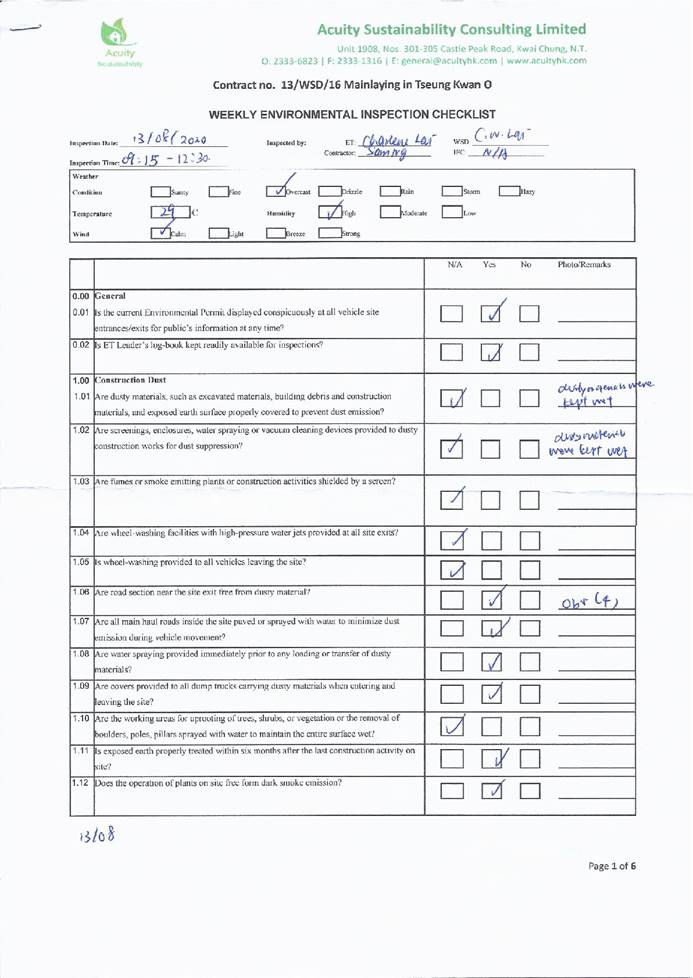

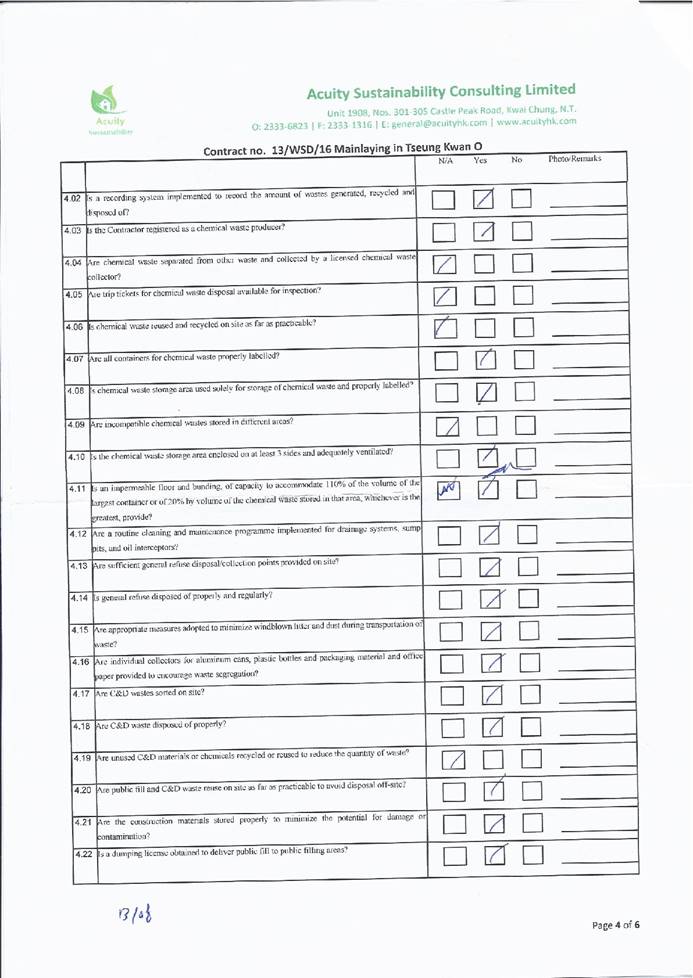

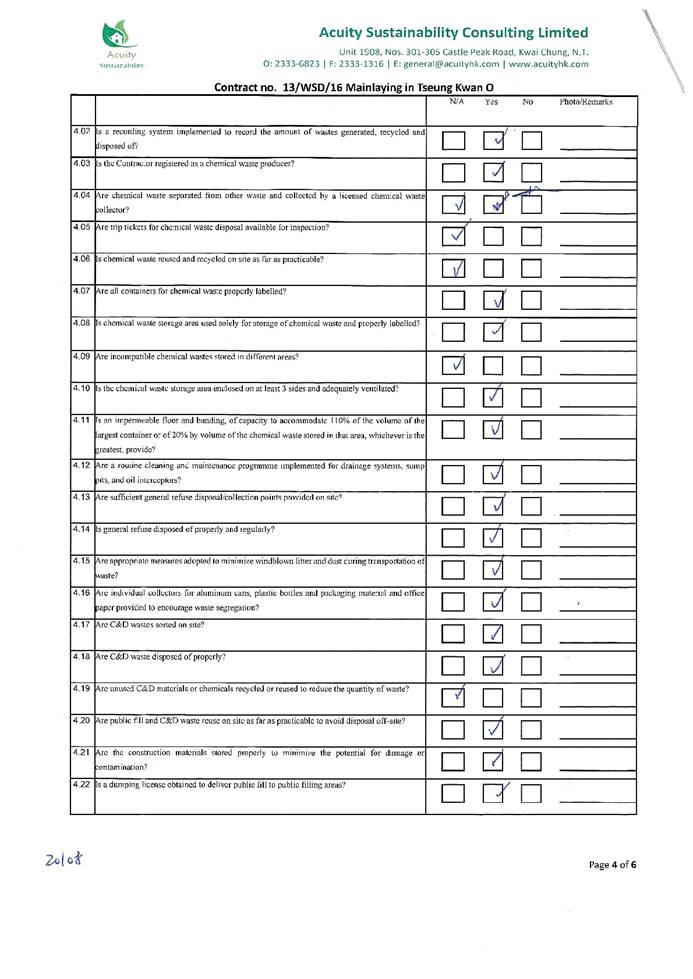

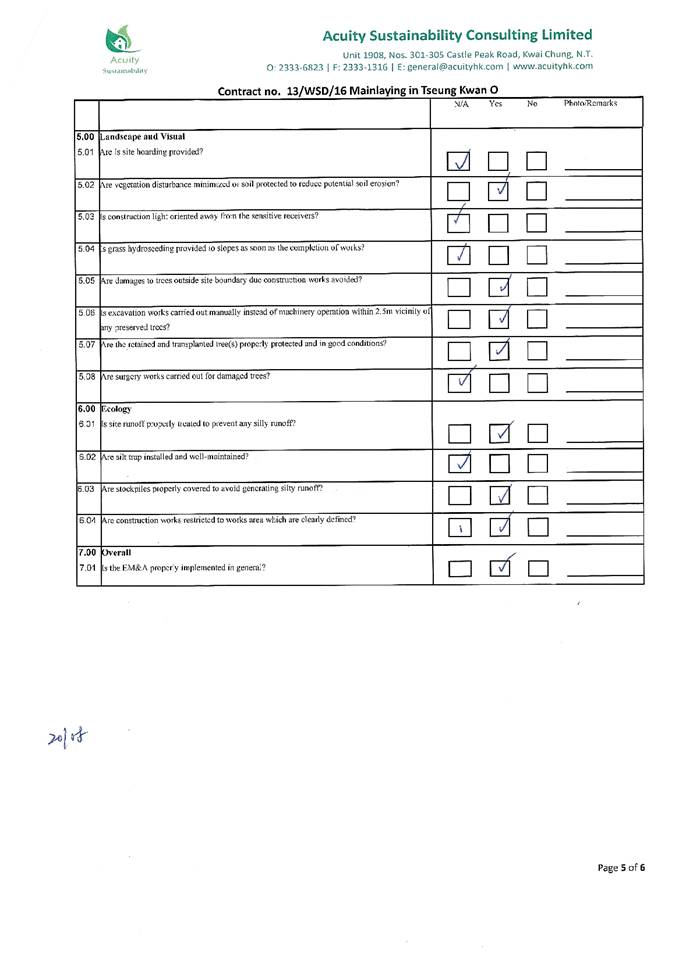

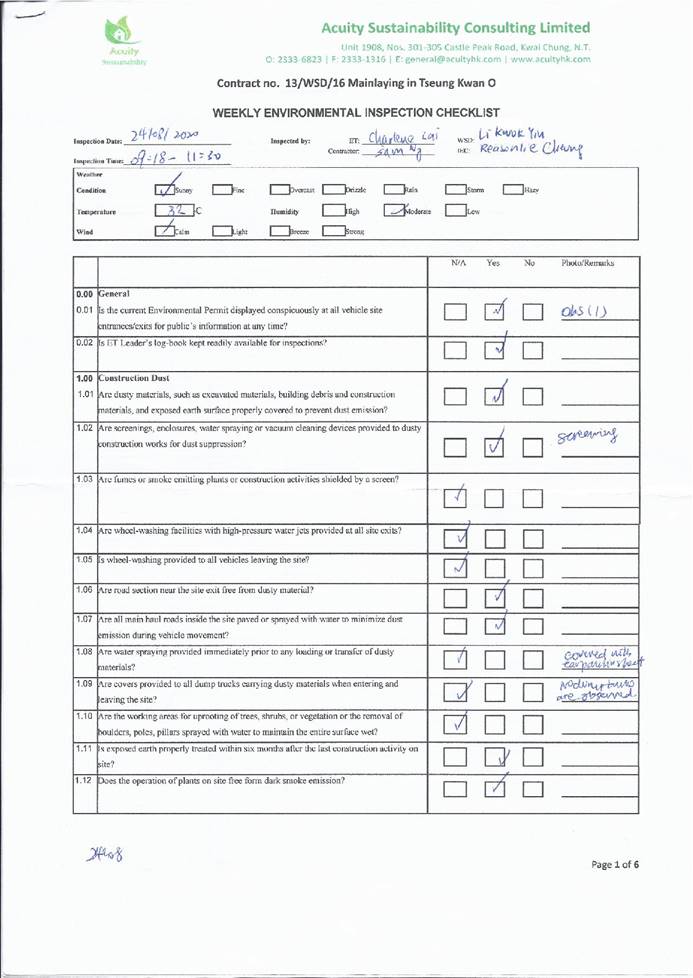

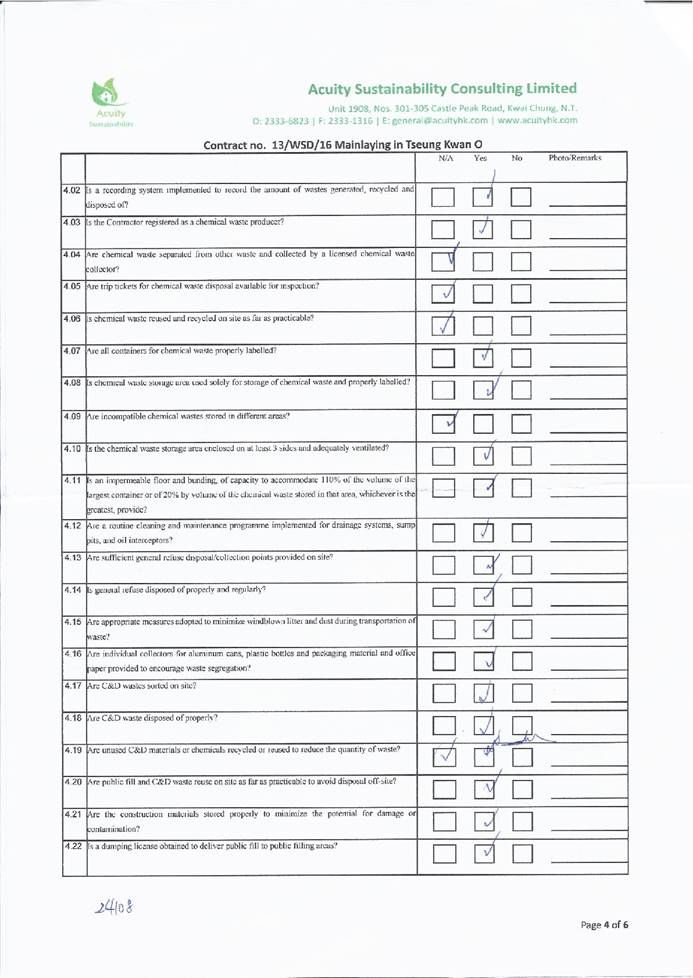

Waste Management

|

|

S8.5

|

Nomination of approved personnel to be responsible for

standard site practices, arrangements for collection and effective disposal to an appropriate facility of all wastes

generated at the site.

|

Contract mobilisation/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

-

|

|

S8.5

|

Training of site personnel in proper waste management and chemical handling procedures. Training will be provided to workers on

the concepts of site cleanliness and appropriate waste management procedures, including waste reduction, reuse

and recycling at the beginning of the construction works.

|

Contract mobilisation/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

-

|

|

S8.5

|

Provision of sufficient waste disposal points and regular collection for

disposal.

|

All area/ During construction/ During operation

|

Contractor(s)

|

|

ü

|

ü

|

Implemented

|

DEVB TC(W)

No. 8/2010, Enhanced Specification for Site Cleanliness

and Tidiness.

|

|

S8.5

|

Appropriate measures to reduce windblown litter and dust

transportation of waste

by either covering trucks or by transporting wastes in enclosed containers.

|

All area/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

DEVB TC(W)

No. 8/2010,

Enhanced Specification for Site Cleanliness and Tidiness.

|

|

S8.5

|

A waste

management plan (WMP)

as stated in

the “ETWB

TC(W) No. 19/2005, Environmental Management on Construction

Sites”

for the amount

of waste generated, recycled and disposed of (including the disposal

sites) will be established and implemented during the construction phase as part

of the Environmental Management Plan (EMP). The Contractor

will be required to prepare the EMP and submits it to the Architect/ Engineer under the Contract for approval prior to implementation.

|

All area/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

ETWB TC(W)

No. 19/2005,

Environmental Management on Construction Sites

|

|

S8.5

|

Separation of chemical wastes for special handling and

appropriate treatment at the Chemical Waste Treatment Centre

at Tsing Yi.

|

All area/ During construction

|

Contractor(s)

|

|

ü

|

|

N/A

|

Chapters 2 &

3 Code of Practice on the Packaging, Labelling &

Storage of Chemical Wastes published under

the Waste Disposal Ordinance (Cap

354),

Section 35

|

|

S8.5

|

Regular cleaning and maintenance programme for drainage systems, sumps

and oil interceptors.

|

Land site/ During

construction

|

Contractor(s)

|

|

ü

|

|

Implemented,

rectified after observation

|

Waste Disposal Ordinance (Cap

354)

|

|

S8.5

|

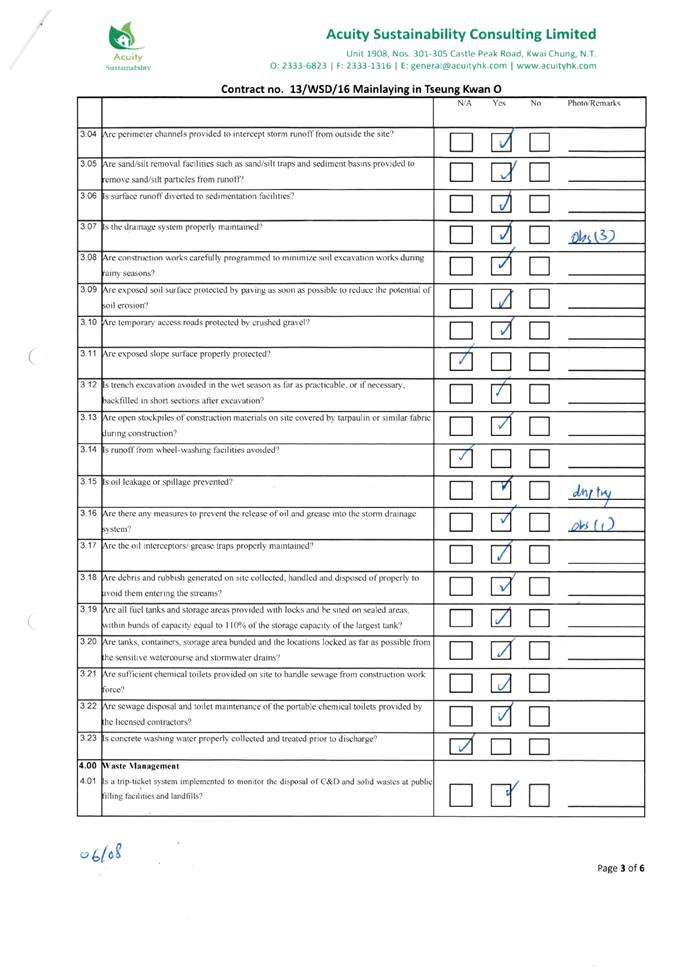

A recording system for the amount

of wastes generated/ recycled and disposal sites. The trip- ticket system

will be included as one of the contractual requirements and implemented by the contractor(s).

|

Land site/ During

construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

DEVB TC(W)

No. 6/2010,

Trip Ticket

System for Disposal of Construction &

Demolition Materials

|

|

S8.5

|

Segregation and storage of different types of waste in different containers, skips or stockpiles to enhance

reuse or recycling of material and their

proper disposal.

|

Land site/ During

construction/ During

operation

|

Contractor(s)

|

|

ü

|

|

Implemented

|

WBTC 32/92, The Use of Tropical Hard Wood

on Construction Site

|

|

S8.5

|

Encourage collection of aluminium cans

and waste paper by individual collectors during

construction with separate labelled bins provided to segregate these wastes

from other general refuse by the workforce.

|

Land site/

During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

ETWB TCW No. 33/2002,

Management of Construction and Demolition Material Including Rock

|

|

S8.5

|

Any unused chemicals and those

with remaining functional capacity will

be recycled as far as

possible.

|

Land site/ During

construction

|

Contractor(s)

|

|

ü

|

|

N/A

|

-

|

|

S8.5

|

Use of reusable non-timber formwork to reduce the amount

of C&D materials.

|

All areas/ During construction

|

Contractor(s)

|

|

ü

|

|

N/A

|

WBTC 32/92, The Use of Tropical Hard Wood

on Construction Site

|

|

S8.5

|

Prior to disposal of construction waste, wood, steel and other metals will

be separated to the extent practical, for re-use

and/or recycling to reduce the quantity of waste

to be disposed of to landfill.

|

All areas/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

DEVB TC(W)

No. 6/2010,

Trip Ticket

System for Disposal of Construction &

Demolition Materials

|

|

S8.5

|

Proper storage and site practices to reduce the potential for

damage or contamination of construction materials.

|

All areas/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented,

rectified after observation

|

-

|

|

S8.5

|

Plan and stock construction

materials carefully to reduce amount

of waste generated and avoid unnecessary generation of waste.

|

All areas/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

-

|

|

S8.5

|

A Sediment Quality Report

(SQR) for sampling and chemical testing of the sediment will be prepared and submitted to

the EPD for approval. The approved detailed sampling and chemical testing will

be carried out

prior to the commencement of the dredging activities to confirm

the sediment disposal method.

|

Marine works/ During construction

|

Contractor(s)

|

|

ü

|

|

N/A

|

ETWB TC(W)

No. 34/2002

and Dumping at Sea Ordinance (DASO)

|

|

S8.5

|

The management of dredged/ excavated sediment

management requirement from ETWB

TC(W) No. 34/2002 will be incorporated in the Specification of the Contract Documents.

|

Marine works/ During construction

|

WSD/ Contractor(s)

|

|

ü

|

|

Implemented

|

ETWB TC(W)

No. 34/2002 and Dumping

at Sea Ordinance (DASO)

|

|

S8.5

|

The contractor will

open a billing account with EPD in accordance with the Waste Disposal (Charges for

Disposal of Construction Waste) Regulation for the payment of disposal charges.

|

Contract mobilisation/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

Cap 354N

Waste Disposal (Charges for Disposal of Construction Waste) Regulation

|

|

S8.5

|

A trip-ticket system

will be established in accordance with DEVB

TC(W) No. 6/2010 to monitor the reuse

of surplus excavated materials off-site and disposal of construction waste and general refuse

at transfer facilities/ landfills, and to control fly-tipping.

|

Contract mobilisation/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

DEVB TC(W)

No. 6/2010,

Trip Ticket

System for Disposal of Construction &

Demolition Materials

|

|

S8.5

|

The project proponent will also conduct regular

inspection of the waste management measures implemented on site

as described in the Waste Management Plan.

|

All area/ During construction

|

Contractor(s)/

Environmental Team (ET)

& Independent Environmental Checker (IEC)

|

|

ü

|

|

Implemented

|

ETWB TC(W)

No. 19/2005,

Environmental Management on Construction Sites

|

|

S8.5

|

A recording system (similar to summary table as shown in Annex 5 and Annex 6 of Appendix G of ETWB TC(W)

No. 19/2005) for the amount of waste

generated, recycled and disposed of (including the disposal sites) will

be established during the construction phase.

|

All area/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

Annex

5 and

Annex 6 of Appendix G of ETWB TC(W)

No. 19/2005

|

|

S8.5

|

Inert C&D materials (public fill) will be reused

within the Project

as far as

practicable.

|

All area/ During construction

|

Contractor(s)

|

|

ü

|

|

N/A

|

-

|

|

S8.5

|

Public fill and construction

waste shall be segregated and

stored in different containers or skips to facilitate reuse

or recycling of materials and their

proper disposal.

|

All area/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

-

|

|

S8.5

|

Specific areas of the work

site will be designated for such segregation and storage

if immediate use is not practicable.

|

All area/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

-

|

|

S8.5

|

To reduce the potential dust

and water quality impacts of site

formation works, C&D

materials will be wetted as

quickly as possible

to the extent practice after filling.

|

All area/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

Air Pollution Control (Construction Dust) Regulation (Cap 311R); WPCO (Cap

358)

|

|

S8.5

|

Open stockpiles of excavated/ fill materials or construction wastes on-site

should be covered with tarpaulin or

similar fabric.

|

Land site/ During

Construction, particularly dry season

|

Contractor(s)

|

|

ü

|

|

Implemented,

rectified after observation

|

Air Pollution Control (Construction Dust) Regulation (Cap 311R)

|

|

S8.5

|

Chemical

waste container shall

be suitable for

the substance they are holding, resistant to corrosion, maintained in a good

condition, and securely closed.

|

All area/ During construction/ During

operation

|

Contractor(s)/

WSD

|

|

ü

|

ü

|

Implemented

|

Waste Disposal (Chemical Waste) (General) Regulation; Code of Practice on

the Packaging, Handling and Storage

of Chemical Wastes

|

|

S8.5

|

Chemical waste container shall have a

capacity of less

than 450 L unless the specifications have

been approved by the EPD.

|

All area/ During construction/ During

operation

|

Contractor(s)/ WSD

|

|

ü

|

ü

|

Implemented

|

Waste Disposal (Chemical Waste) (General) Regulation; Code of Practice on

the Packaging, Handling and Storage

of Chemical Wastes

|

|

S8.5

|

A label in English

and Chinese shall be displayed on the chemical container in accordance with instructions prescribed in Schedule 2 of the Regulations.

|

All area/ During construction/ During

operation

|

Contractor(s)/ WSD

|

|

ü

|

ü

|

Implemented

|

Waste Disposal (Chemical Waste) (General) Regulation; Code of Practice on

the Packaging, Handling and Storage

of Chemical Wastes

|

|

S8.5

|

Storage areas for chemical waste shall

be enclosed on at least 3

sides.

|

All area/ During construction/ During

operation

|

Contractor(s)/ WSD

|

|

ü

|

ü

|

Implemented

|

Waste Disposal (Chemical Waste) (General) Regulation; Code of Practice on

the Packaging, Handling and Storage

of Chemical Wastes

|

|

S8.5

|

Storage areas for

chemical waste

shall have an impermeable floor and bunding, of capacity to accommodate 110%

of the volume

of the largest

container or 20% by volume of the chemical waste stored

in that area,

whichever is

the greatest.

|

All area/ During construction/ During

operation

|

Contractor(s)/ WSD

|

|

ü

|

ü

|

Implemented

|

Waste Disposal (Chemical Waste) (General) Regulation; Code of Practice on

the Packaging, Handling and Storage

of Chemical Wastes

|

|

S8.5

|

Storage areas for chemical waste shall

have adequate ventilation.

|

All area/ During construction/ During

operation

|

Contractor(s)/ WSD

|

|

ü

|

ü

|

Implemented

|

Waste Disposal (Chemical Waste) (General) Regulation; Code of Practice on

the Packaging, Handling and Storage

of Chemical Wastes

|

|

S8.5

|

Storage areas for chemical waste shall

be covered to prevent rainfall entering (water collected within the bund

must be tested and

disposed of as chemical waste,

if necessary).

|

All area/ During construction/ During

operation

|

Contractor(s)/

WSD

|

|

ü

|

ü

|

Implemented

|

Waste Disposal (Chemical Waste) (General) Regulation; Code of Practice on

the Packaging, Handling and Storage

of Chemical Wastes

|

|

S8.5

|

Storage areas for

chemical waste

shall be arranged so that incompatible materials are appropriately separated.

|

All area/ During construction/ During

operation

|

Contractor(s)/ WSD

|

|

ü

|

ü

|

Implemented

|

Waste Disposal (Chemical Waste) (General) Regulation; Code of Practice on

the Packaging, Handling and Storage

of Chemical Wastes

|

|

S8.5

|

General refuse

will be stored

in enclosed bins or compaction units separately from construction and

chemical wastes.

|

All area/ During construction/ During

operation

|

Contractor(s)/ WSD

|

|

ü

|

ü

|

Implemented

|

Waste Disposal (Chemical Waste) (General) Regulation; Code of Practice on

the Packaging, Handling and Storage

of Chemical Wastes

|

|

S8.5

|

Adequate number of waste

containers will

be provided to avoid over-spillage of waste.

|

All area/ During construction/ During

operation

|

Contractor(s)/ WSD

|

|

ü

|

ü

|

Implemented

|

DEVB TC(W)

No. 8/2010

Enhanced Specification for Site Cleanliness and Tidiness.

|

|

S8.5

|

A reputable waste

collector will

be employed by the Contractor to remove general refuse

from the site,

separately from

construction and chemical wastes, on a daily

basis to minimise odour, pest and litter impacts.

|

All area/ During construction/ During

operation

|

Contractor(s)/ WSD

|

|

ü

|

ü

|

N/A

|

-

|

|

S8.5

|

Recycling bins will be provided at strategic locations within

the Site to facilitate recovery of recyclable materials (including aluminium can,

waste paper,

glass bottles and plastic bottles) from the

Site.

Materials recovered will be sold for recycling.

|

All area/ During construction/ During

operation

|

Contractor(s)/

WSD

|

|

ü

|

ü

|

Implemented

|

-

|

|

S8.5

|

To avoid

any odour and litter impact, accurate number of portable toilets will be provided for

workers on-site.

|

All area/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

-

|

|

S8.5

|

The burning of refuse

on construction sites

is prohibited by law.

|

All area/ During construction

|

Contractor(s)

|

|

ü

|

|

Implemented

|

Air Pollution Control Ordinance (Cap 311)

|

|

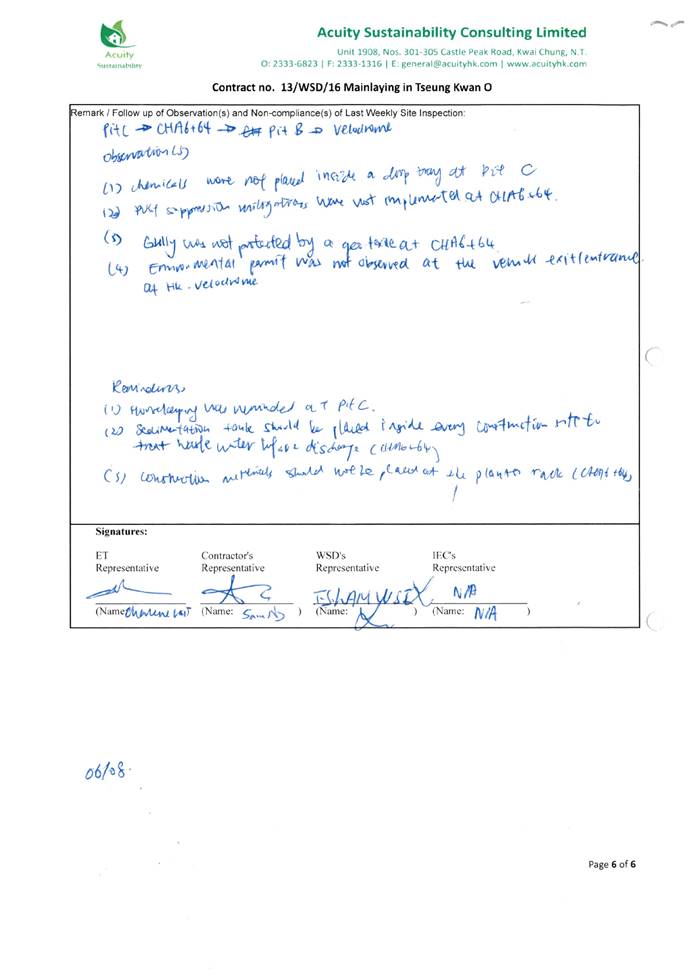

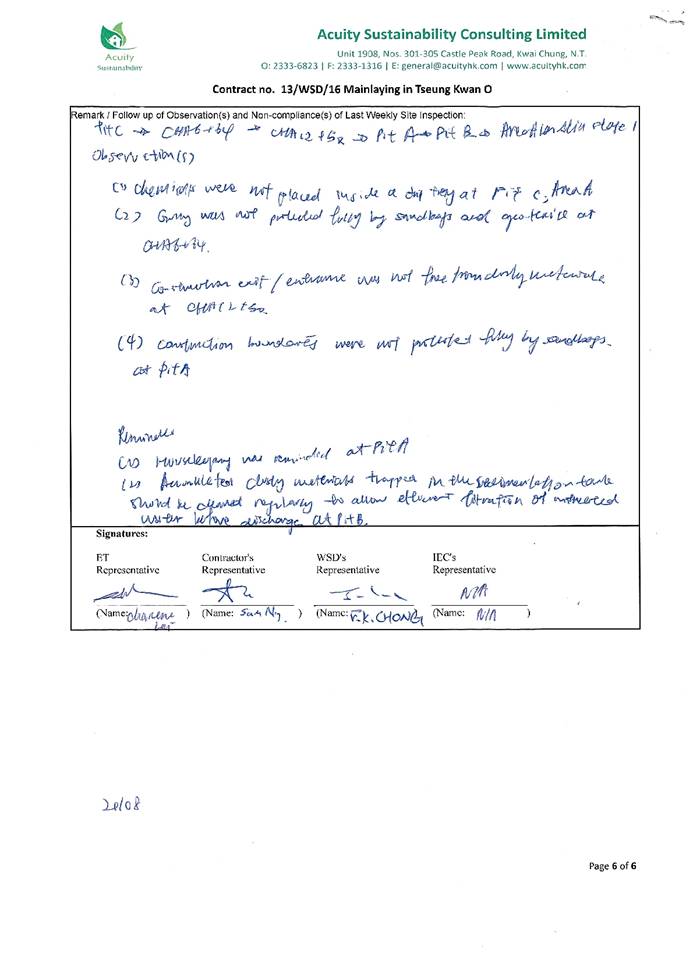

S8.7

|

To facilitate monitoring and control

over the contractors’ performance on waste management, a waste inspection

and audit programme will be

implemented throughout the construction phase.

|

All facilities/ During construction

|

ET/ IEC

|

|

ü

|

|

Implemented

|

-

|